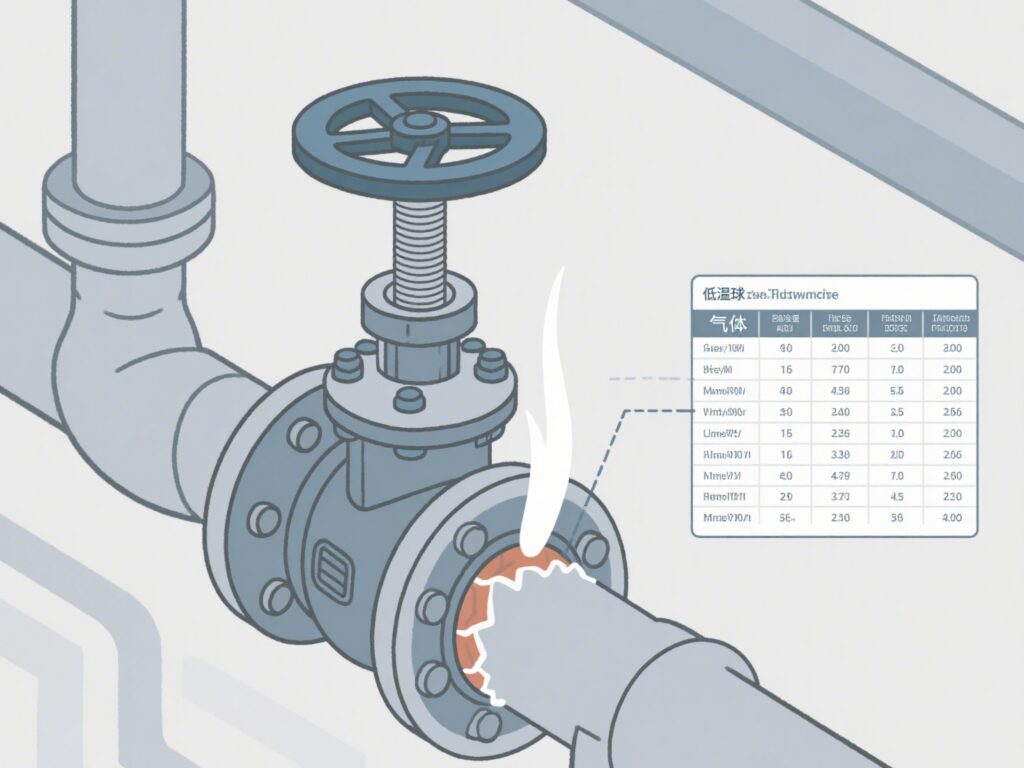

Besides the design of the sealing structure, there are many other factors that affect the sealing performance of low-temperature ball valves, such as the material of the sealing pair, the quality of the sealing pair, the sealing specific pressure, and the physical properties of the medium. These factors all have a significant impact on the valve’s performance. When designing a valve, it is essential to consider the influence of these factors as much as possible to ensure its normal working state.

1. Sealing Pair Material

Under low-temperature conditions, the deformation of the sealing pair material should be taken into account. Metal materials will shrink as the temperature decreases, resulting in gaps at the sealing point and a reduction in the sealing specific pressure, thereby affecting the sealing performance. Therefore, when designing the sealing structure, it is crucial to select a reasonable sealing material to ensure tightness. In LNG working conditions, a soft sealing method combining metal and non-metallic materials is mostly adopted. On one hand, this can reduce friction during valve opening and closing, prolonging the valve’s service life; on the other hand, it has lower costs and better sealing performance. The sealing material is mostly polychlorotrifluoroethylene, as it has good sealing performance regardless of the working medium. However, polytetrafluoroethylene is not suitable because it undergoes cold flow at low temperatures.

2. Sealing Pair Quality

The quality of the sealing pair is mainly reflected in the surface processing quality of the ball and the surface roughness of the sealing surface. Improving the roundness of the ball and reducing its surface roughness can reduce the torque during valve opening and closing, increase the valve’s service life, and also improve its sealing performance. Therefore, improving the surface processing quality of the sealing pair is very important in the design process.

3. Sealing Specific Pressure

Sealing specific pressure refers to the pressure per unit area of the sealing surface. The magnitude of the sealing specific pressure directly affects the tightness, reliability, and service life of the ball valve. However, the sealing specific pressure borne by the valve ball is not the higher the better. A relatively large sealing specific pressure is beneficial to sealing to a certain extent, but as the sealing specific pressure increases, the torque required for valve operation also increases, which is not conducive to the normal operation of the valve. Therefore, the selection of sealing specific pressure is another important aspect in the sealing design of ultra-low-temperature ball valves.

4. Physical Properties of the Medium

The physical properties of the medium, such as viscosity and temperature, have a certain impact on sealing. Firstly, the higher the viscosity of the medium, the lower its permeability, making it less likely to leak. The influence of the medium’s temperature on sealing is mainly reflected in low-temperature conditions: changes in the size of some sealing components cause changes in the sealing structure, leading to leakage. At the same time, changes in the sealing pressure in the sealing area can also damage the seal. Therefore, the influence of temperature must be considered when designing the sealing structure.